With our vast experience of over 20 years in the food and beer production industry, we have developed and implemented several technological solutions for problems presented in these industries. Besides these products, that we like to present as an example, we have also developed a wide range of applications in different fields of modern industry have the ability to give specific solutions to the specific needs of each client.

For more information about products and capabilities of our company, please contact us

“Lauter Regulation”

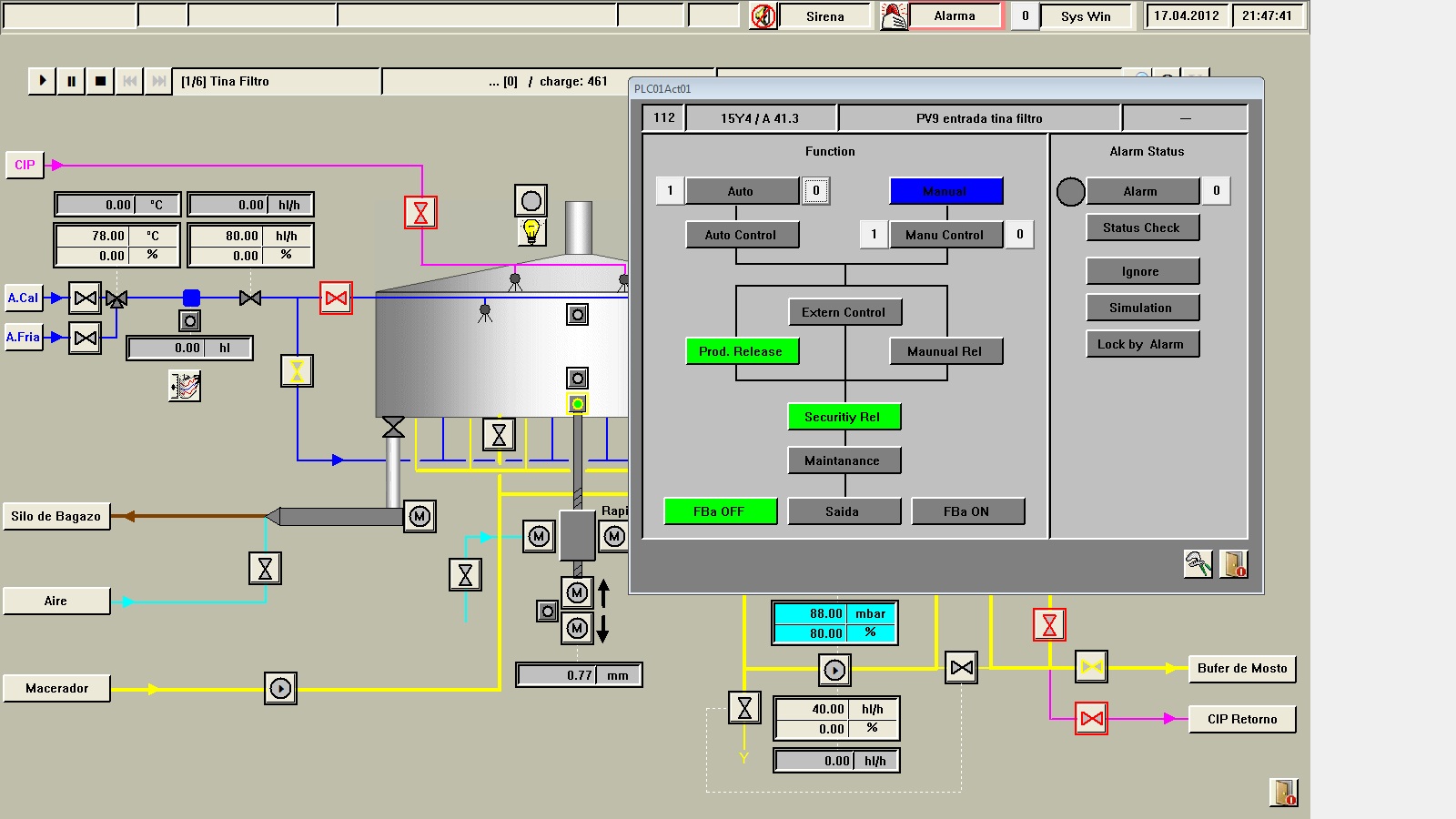

This technological Application represents our system for regulation and control for clarification process (“Lautering”) found in most breweries of all sizes.

In most brew houses the lauter tun is the bottleneck in the production. This means, by optimizing the software you will increase the productivity. This system can be implemented in breweries of all sizes and is designed to use existing equipment in the best possible way. This system implements its regulation mechanisms on the basis of “Fuzzy Logic” to produce the best possible Quality and process time, even though the process parameters are adjustable.

For more detailed information and reference implementations, please check our PDF presentation.

|

|

Dosing control for Kieselguhr filtration

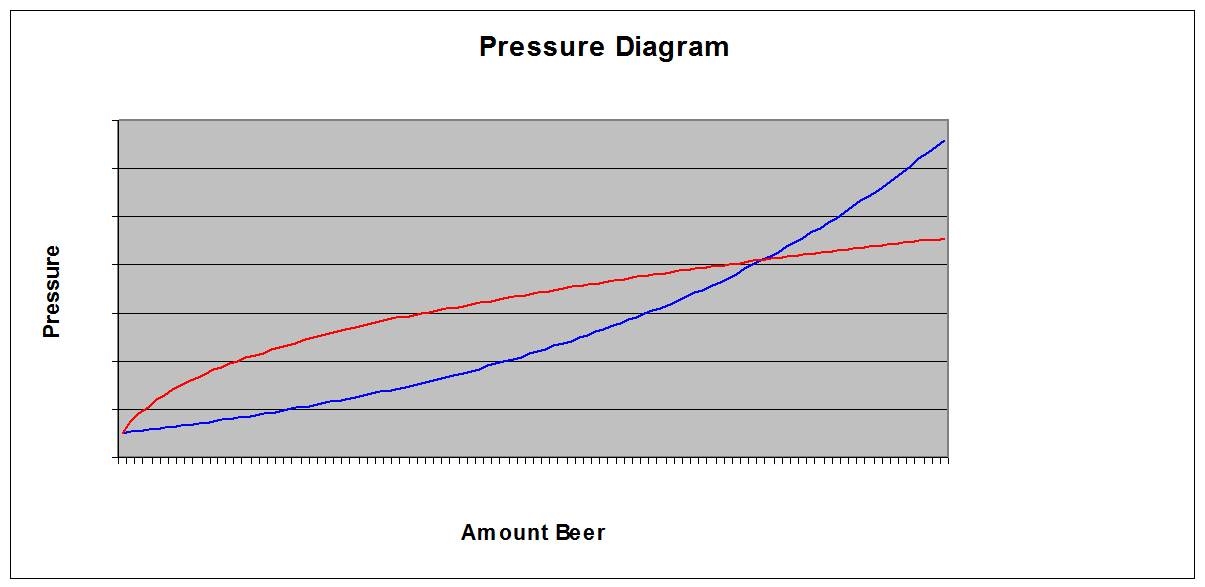

In modern Kieselguhr filtration, both Horizontal and candles filters, it is crucial to have a efficient and reliable monitoring and control software for the Kieselguhr dosing, to achieve an optimal filtration performance of the filtration system. This system automatically optimizes the use of filtration earth to achieve higher filtration time and considering the current performance parameters (pressure , flow, turbidity optionally). Our regulation is based on “FUZZY LOGICS” Regulations, which allows to anticipate possible changes in process conditions (such as excessive increases in the amounts of yeast caused by a change in the filtration tank ), and acting accordingly by adjusting the necessary nominal values in real time for optimum filtration, maximizing the efficiency of the process. The system constantly monitors the behavior of the filter pressure, always considering optimal performance, and uses these values to determine the amount of filtration earth needed for dosing .

- Optimize filtration times

- anticipate possible changes in process conditions to react appropriately, providing greater stability to the process.

- eliminate the supervision and monitoring of operators in the dosing process of the filtration.

Several successful implementations further prove the efficiency of this control system. For more information about our system please contact us.

|