BatchXpert is a Batch process control, management and reporting system for small and mid-sized applications. It can manage the production and reporting of all sorts of batch processes especially for the food and beverage industry.

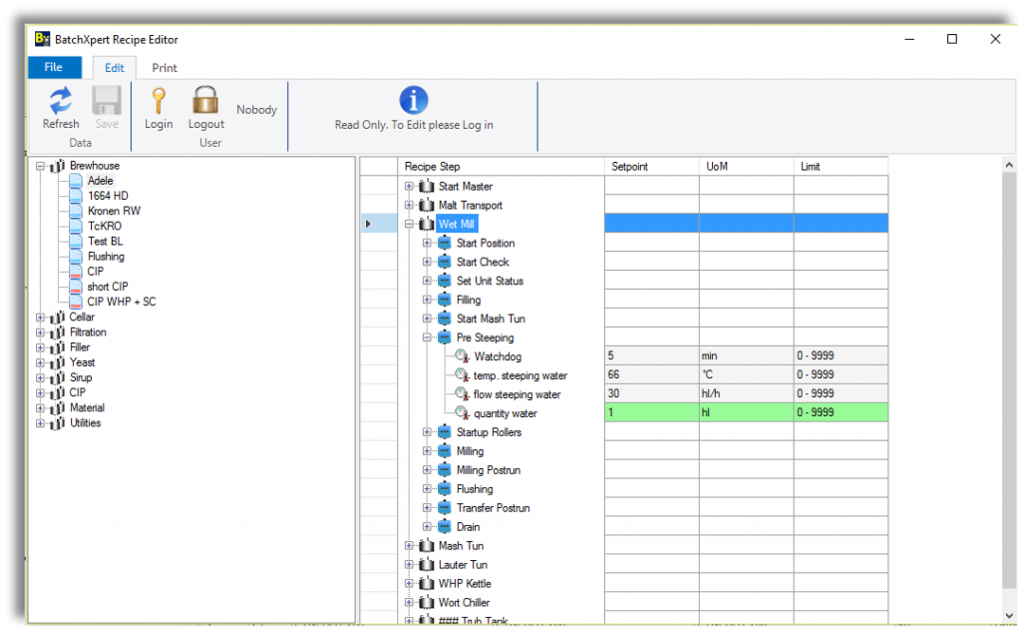

It provides tools for creating, managing and execution of Recipes and automatically creates production reports based on the executed Processes. It is the successor of the successful Batch control system “BatchGuide“.

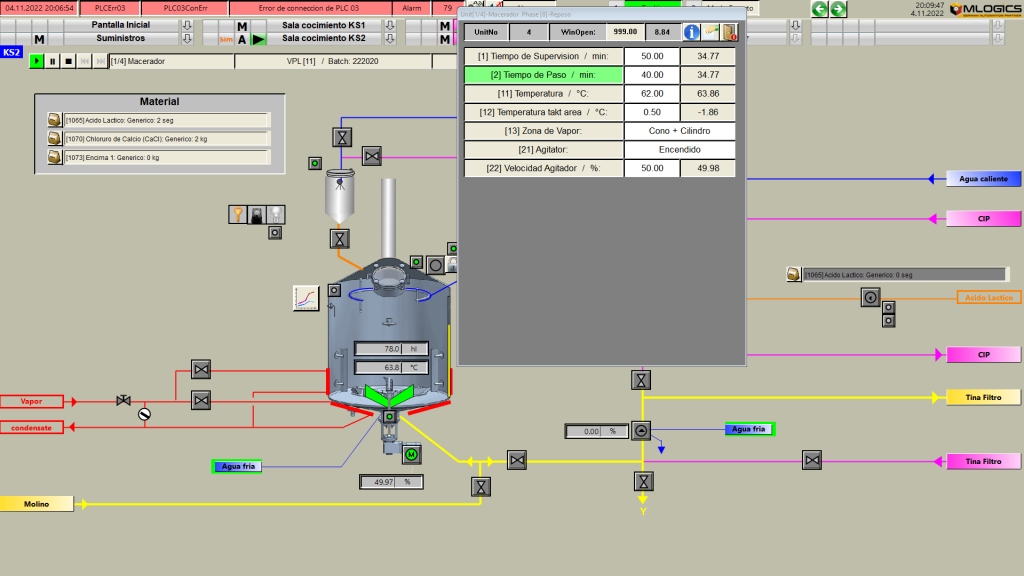

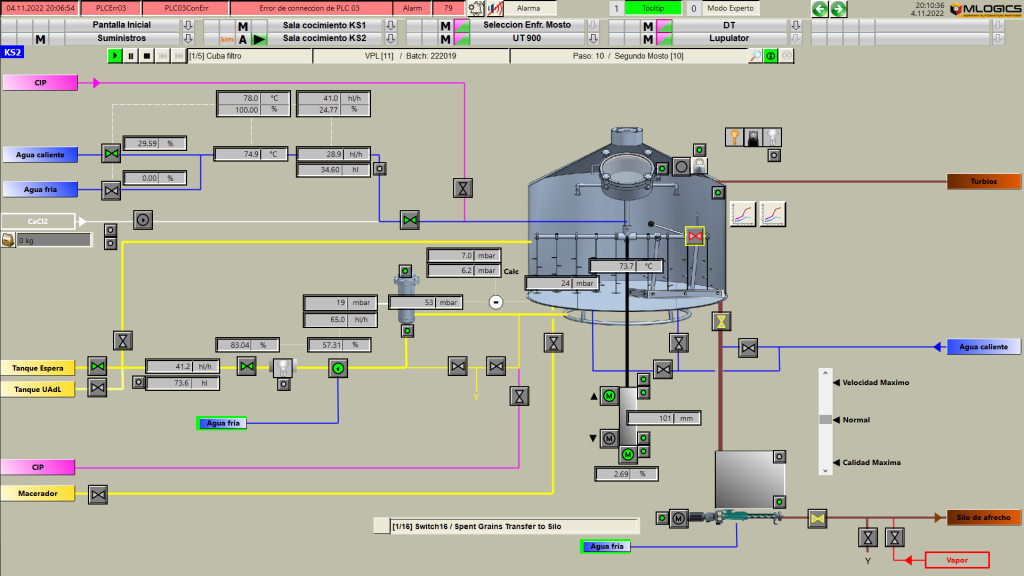

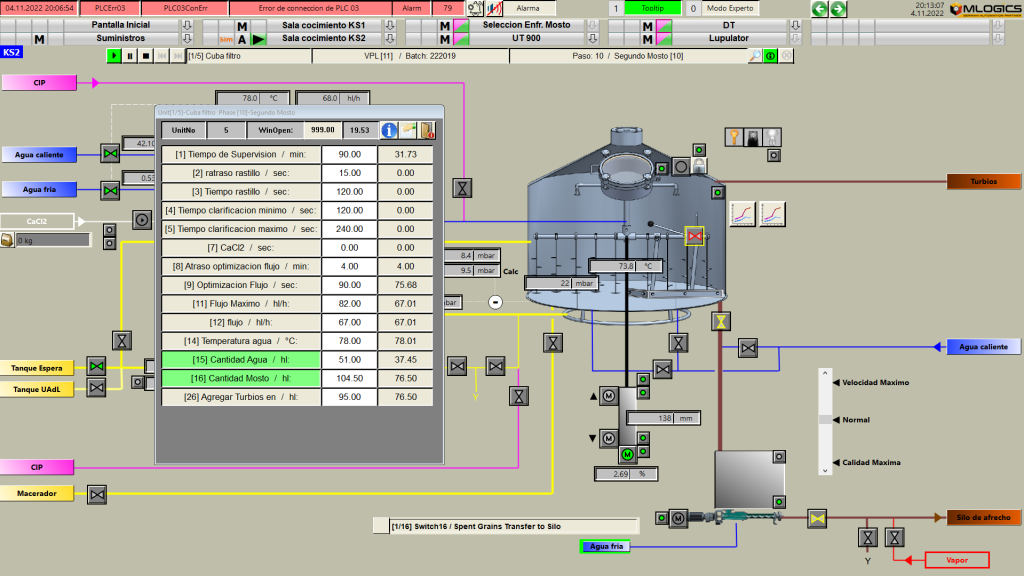

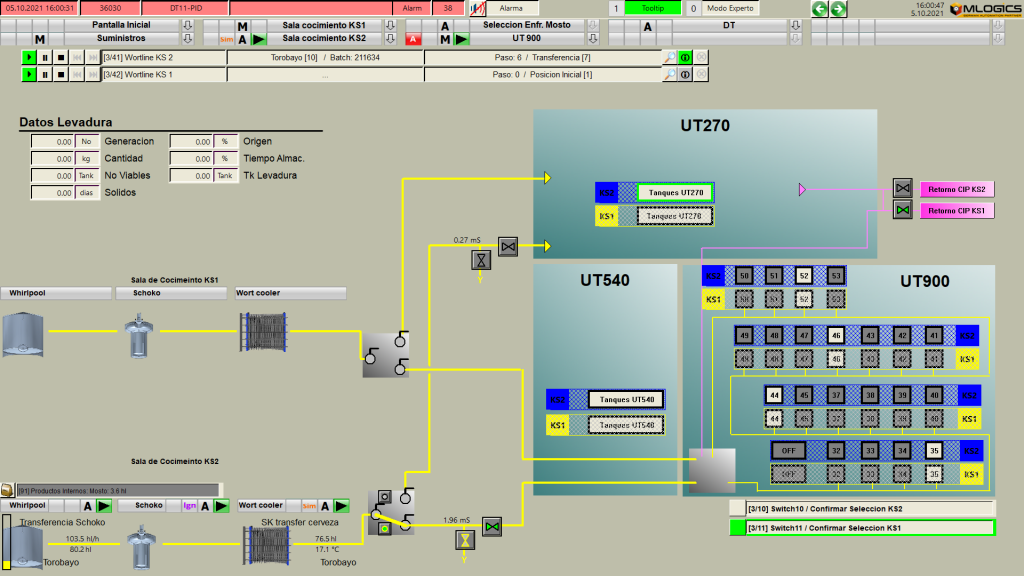

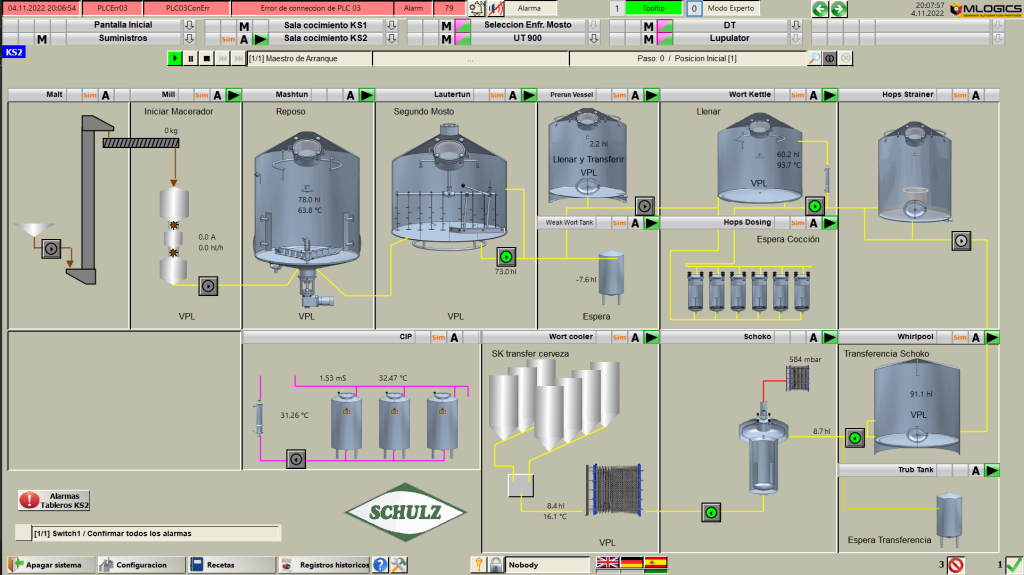

Process Control

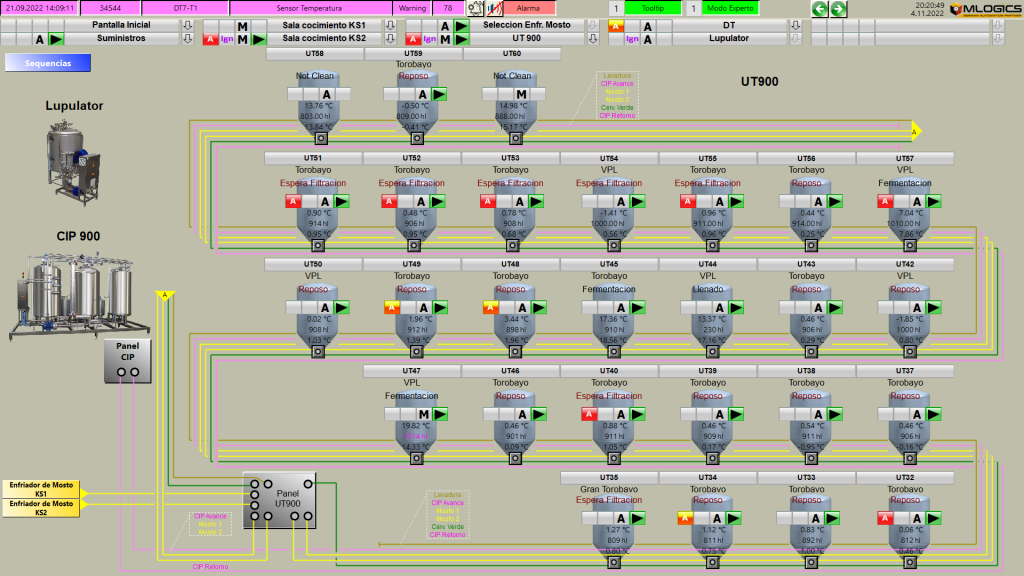

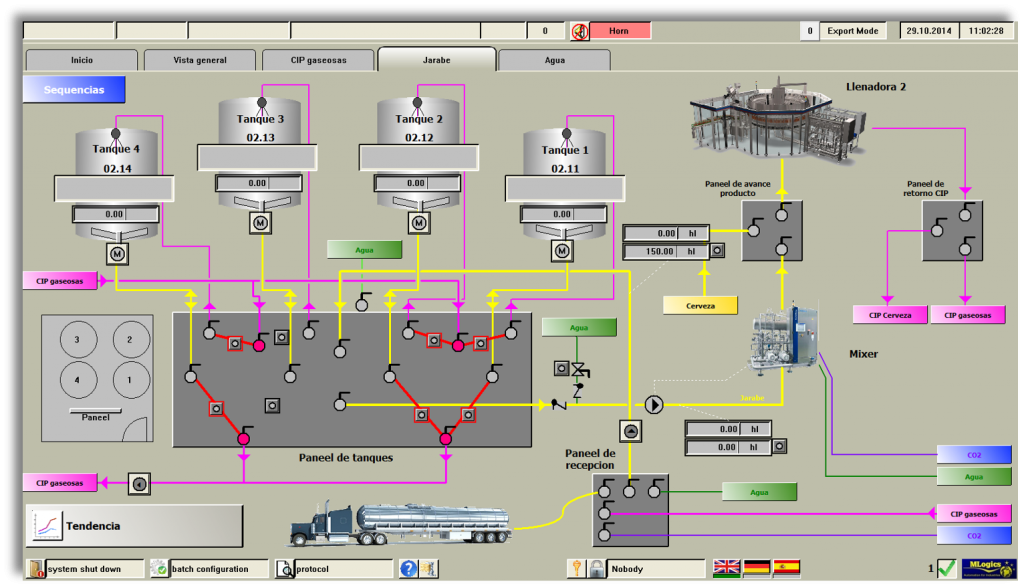

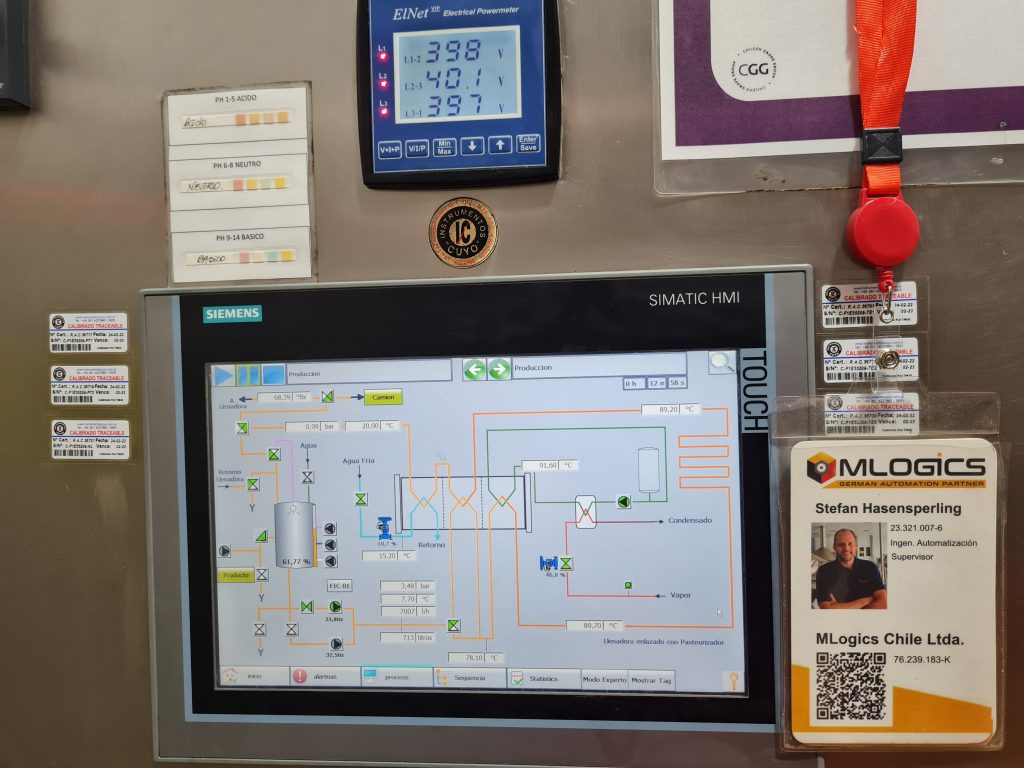

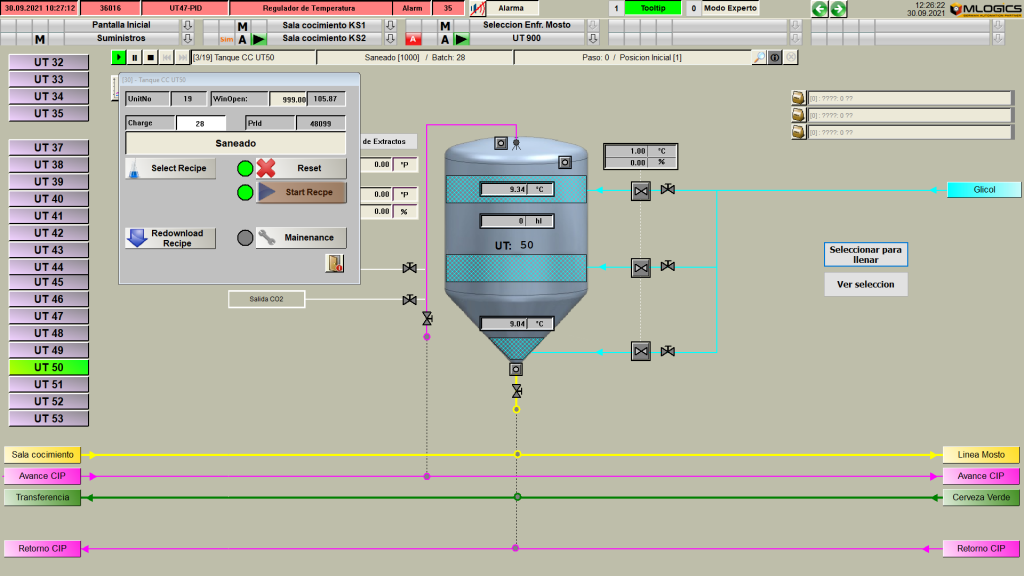

The BatchXpert System incorporates standardized and consistent user interfaces across all processes. All HMI screens are in accordance with established industry standards with a focus on simplicity and allowing an efficient reaction of the operating personnel in all kinds of situations.

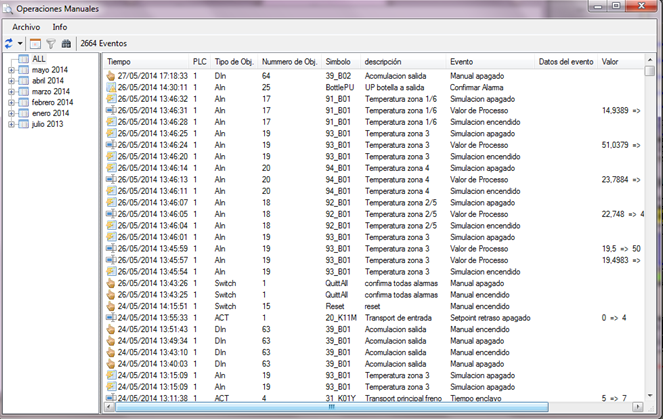

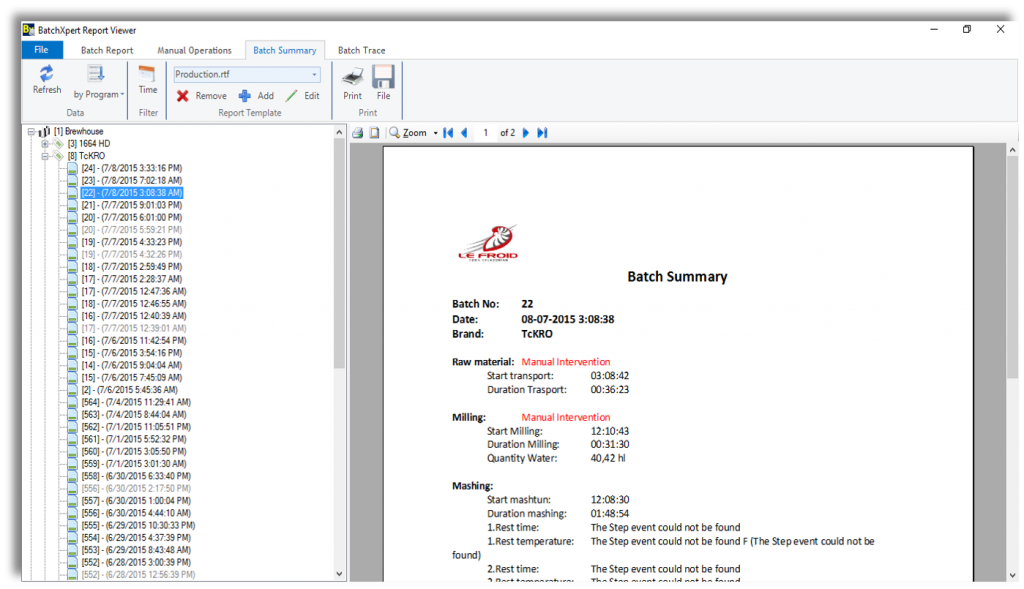

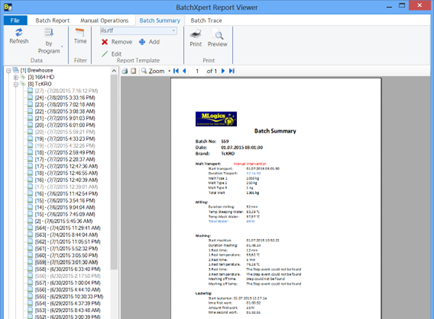

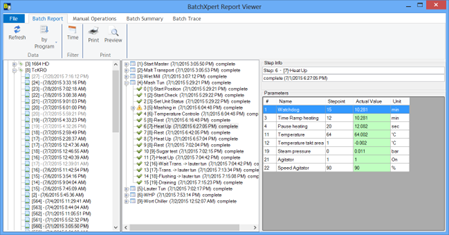

Reporting

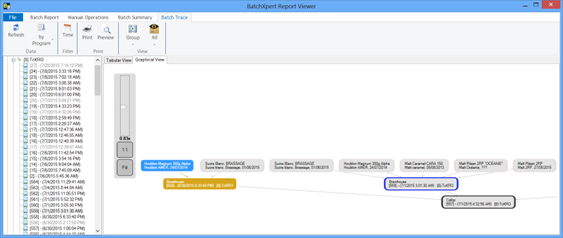

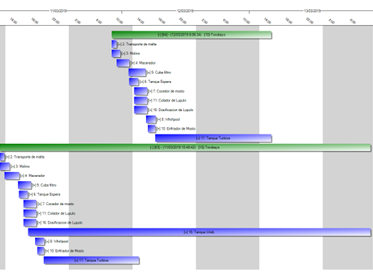

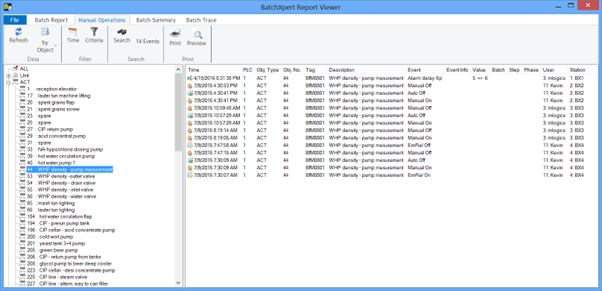

The System incorporates many reporting tools, that let you trace batches, review its process steps and also review any manual interventions made to any equipment involved in any batch process executed by the system. For each Batch, it creates summary and detailed reports, as well as detail trend curve recordings and alarm reports, to enable you to control and optimize any process with ease.

Fault Tolerance

It is designed to be fault tolerant, by distributing the databases to various servers, thus eliminating an single point of failure and keeping the processes running even if servers are failing. Fault tolerance is deeply embedded in the design of the system. If an Server is failing, it can be restored from backup in less than 30 minutes.

Latest Technologies

It uses the latest industrial standard technologies and is constantly updated in order to support new technologies. The system is currently supporting in Windows 10/11 and Sql Server 2005-2022.