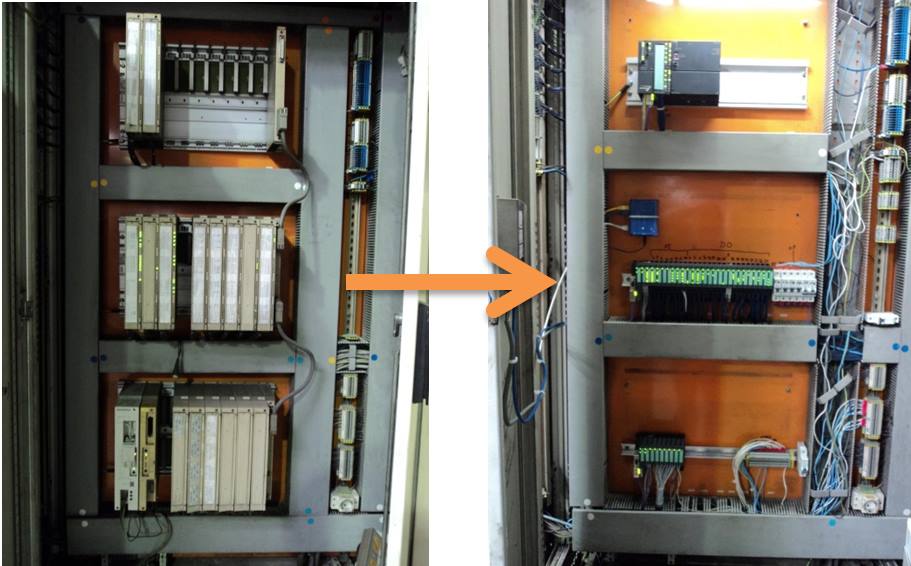

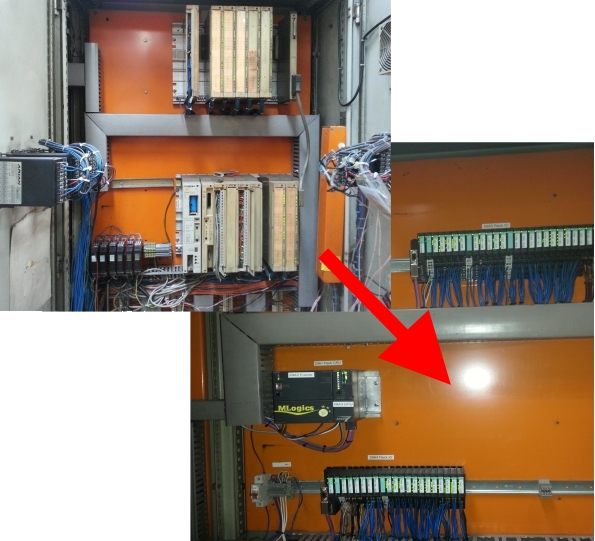

When automation hardware components are changed, you must also set a focus on modernizing also control software. An optimized control software, on basis of “Fuzzy Logic”, helps to improve and stabilize the quality of the product. This monitoring system improved continuity and quality of the pasteurization process through its INNOVATIVE monitoring and control software which is capable of accurately calculate the temperature and the pasteur units value in real time and online for each bottles in the machine.

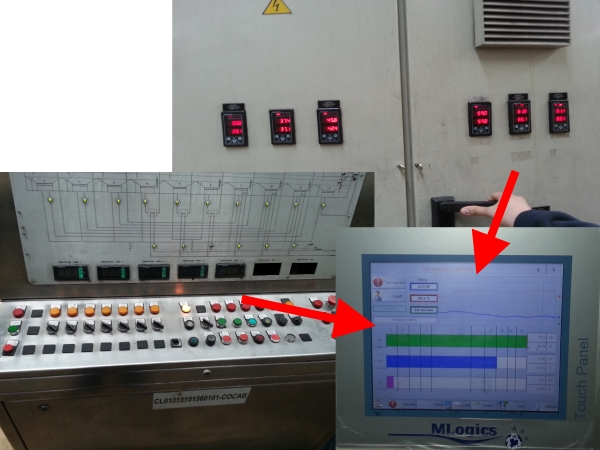

This system can be implemented in all types of tunnel pasteurizers existing on the market today, and it is a very good opportunity to update the control system including both, the hardware and also the software of an existing tunnel pasteurizer.

For more detailed information and referral system, please check our PDF presentation.

Difficulties of an tunnel pasteurization control

The tunnel pasteurization process is a highly complex process and requires a sophisticated control for optimal results .

Making tunnel pasteurization particularly complex , among others, are the following:

- Only a transport for all bottles

- Only a temperature within a zone

example:

- Bottle X, the last bottle of zone 3 at 40 ° C

- Bottle Y, the first bottle of zone 4 to 50 ° C

- Accumulation of 10 Minutes

After 10 minutes, the temperature of bottle X will be at 40°C and of bottle Y 50 ° C Bottle Y. After the acumulation is resolved and the process continues, the bottle and bottles X and Y are in the same area, side by side with a temperature difference of 10°C. The Control system must then set regulate the zone temperature in an way that neither the bottle X nor the bottle Y, will end up out of its Pasteuization Untis limits.

A common control through a simple temperature control, can not resolve these difficulties. An advanced system is required to calculate and control units Pasteur continuous and intelligently.

Intelligent Pasteur Units control

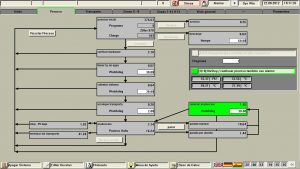

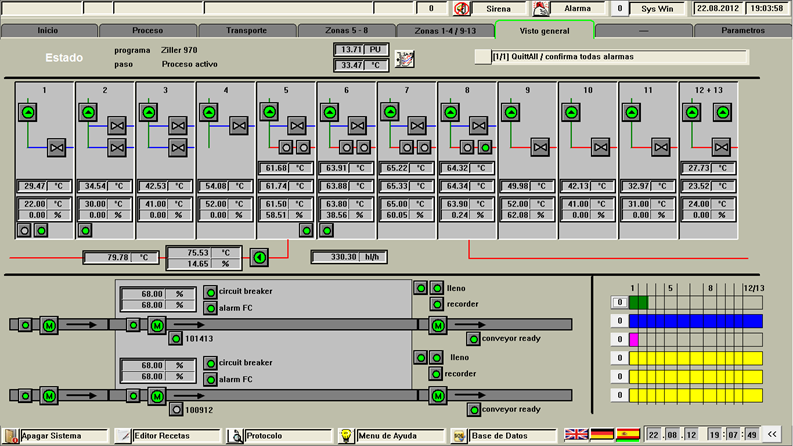

The complex control based on ” Fuzzy Logic” , which considers the UP, temperature, speed and current position of the bottles into the calculation, is able to keep the pasteurized product within its tolerance limits even when during alarms and interruptions of the production process ( jam at the exit, problems in the supply of steam, …).

The system reacts intelligently to the variables of the process:

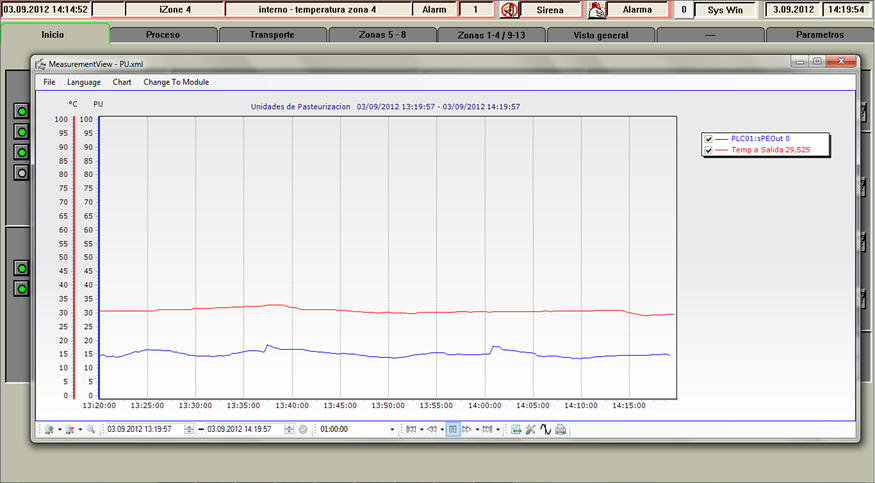

• Continours calculation of temperature and PU for each bottle into the pasteurizer

• Automatic adjustment of the zone temperatures to avoid fluctuations in the process

• Intelligent Stop/Start of the transportation to avoid unpasteurized Product

So you get the following advantages :

• Improved stability of UP

• Intelligent Reaction to faults and problems during the process, avoiding fluctuations in PU

• Better control of PU. The system prevents low pasteurized product

Power Cut

If power returns, the system executes the following routines:

- Measure the time without power

- Mathematical synchronization process: temperature and pasteurization units

- Physical Synchronization: water circulation to ensure a minimum temperature of the bottle

this way the system can calculate Pasteur units of the bottles which increased during the shutdown and prevent product lost due to unknown amount of the units Pasteur

Lowering of temperature during production stops

If there are accumulations at the outlet of the pasteurizer and the process stops, the temperature is lowered gradually while maintaining the limits of the UP for each Zone. This method reduces the restart time of the pasteurizer during production, and also saves energy.

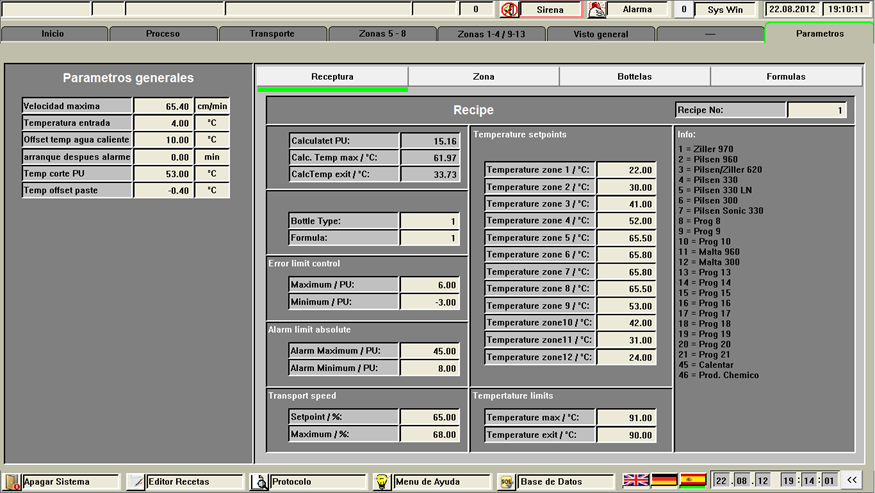

Flexible Parameterization

- You can enter multiple formulas for calculating the PU (Pasteur Units). Each drink has its own calculation formula (Beer, Juice, …).

- You can input characteristics and properties for differents types of bottellas and cans

- In the recipe you can select the formula of calculation and the relevant type of bottle.

- With each recipe adjustment, the operator can immediately see the expected results (Units Pasteur, the maximum temperature in the bottle, …).

- The parameters and the recipe is stored in the PLC. Thus it is possible to operate the system without the computer on (only with touchscreen).

- You can enter new types of bottles and recipes by the operator. Without the need for a programmer

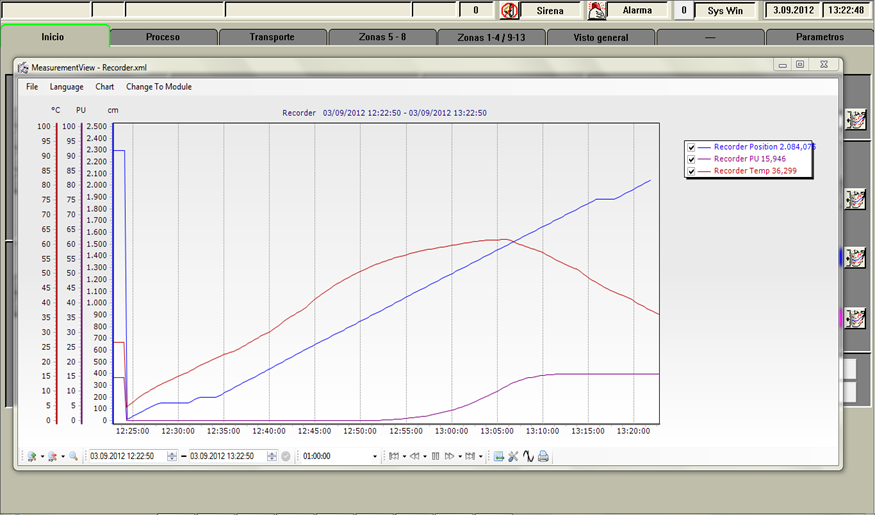

Recording of an virtual Reference Bottle

You can record and display several referenc bottles. In the trend curves one can see the position of the bottle, the temperature curve and the Pasteur units. These recordings can then be compared to an real reference bottle to:

- Check the correct operation of the pasteurizer. If the values of the virtual and real reference bottle are very different, this might indicate problems with temperature sensors, that are loosing their calibration.

- Controlling the properties of the bottle. If the provider is changed, charcteristics of the bottles, such as the thickness of the glass bottle, may have changed as well. This can be detected by this method.

- Optimizing the process

- Under normal circumstances you can reach an accuracy up to +/-1UP of the calculation in respect to a reference bottle.

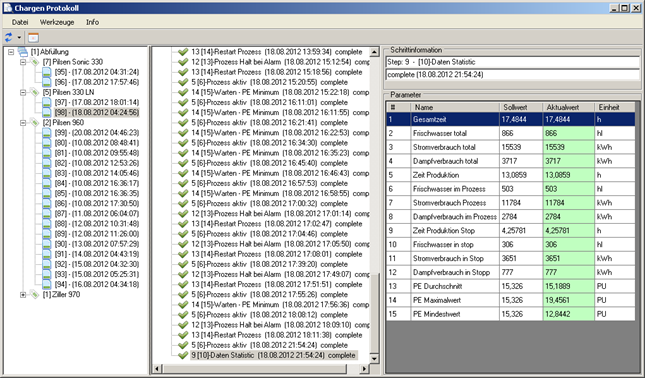

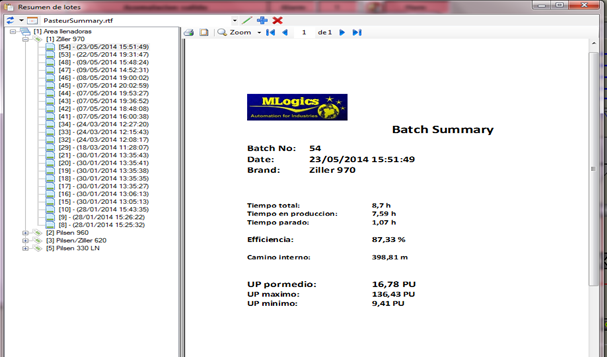

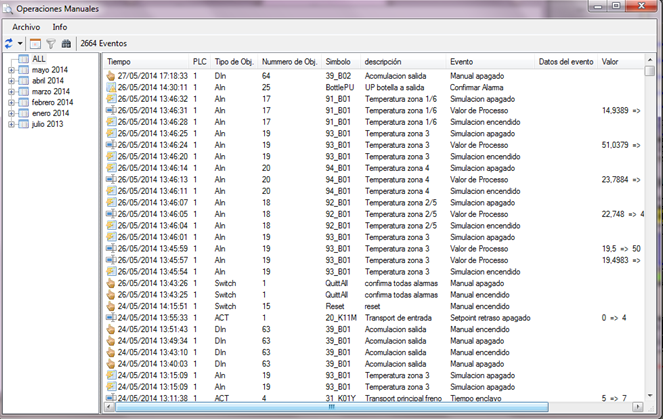

Process Data acquisition

The system uses the historical data acquisition engine of the “BatchXpert” system, which delivers data security on up to 8 parallel servers. The data acquisition system is designed to prevent data loss even when the computers are not working (the PLC continues to record until the memory is full).