BatchGuide is the direct predecessor of the BatchXpert automation system, where various different variables where combined to in the development of an highly sophisticated product. This history began around 1996 when the increasing degree of automation in the production processes of industries, demanded an economical and versatile automation solution, which would incorporate all features of Modern Process Management Systems.

The market

In 1997, a team of Automation and brewing specialists developed a fully featured Automation system (PLC with Display and Process Management) for Breweries on the basis of the SCADA system “GraphPic®” developed by “Gefasoft AG”. This was the birth of the BatchGuide system, and would hit the market until a year later.

Objectives

- Substantially improve the quality to price ratio for an competitive product

- Achieving a simple integration of the system, allowing to meet real world problems existing in automation

- Developing a High Performance system with sufficient capacity to control Breweries in its entirety.

- Create a system that is easy to manage, comfortable to use and simple to operate, to improves the old and complex user interfaces that existed at this time

Development

In 1998, after two years of development, the system hits the market thanks to the high acceptance among customers, began to attract the interest of big companies. This forced the system to grow and implement new functions and features. One of these new features was the implementation of multilingualism with which the BatchGuide System could also Internationally deployed.

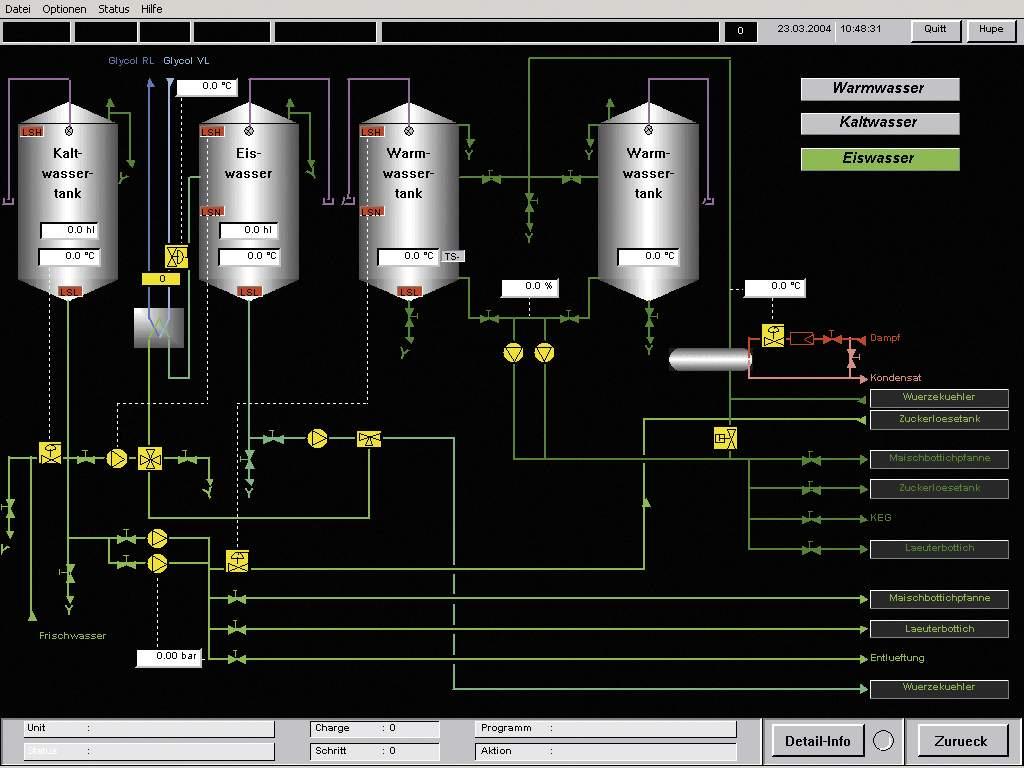

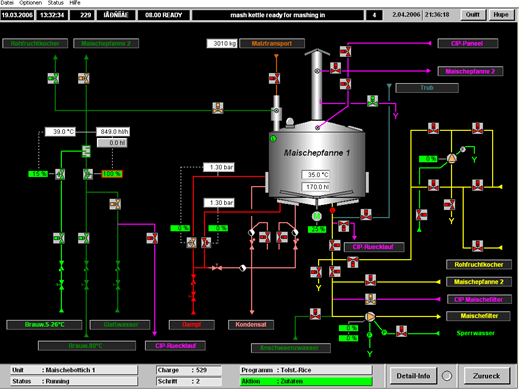

Characteristics of Applications

- Able to produce up to 1,000,000 hecto liters of wort yearly.

- 18 Units can be controlled including approximately 400 valves and motors, more 30 regulators and 50 analog values.

- The 12 types of beers and various CIP programs contain about 2,100 process steps and a total of approximately 12,000 parameters.

- Each of the process steps is recorded in a database, with their respective nominal and actual values.

Recipe Management

A recipe is configurable sequence of steps, running on the PLC tailored to the needs of each plant and able to implement of various products and recipes, since usually in a plant there are plenty of recipes to be implemented. This system allowed the user to manipulate these recipes easily.

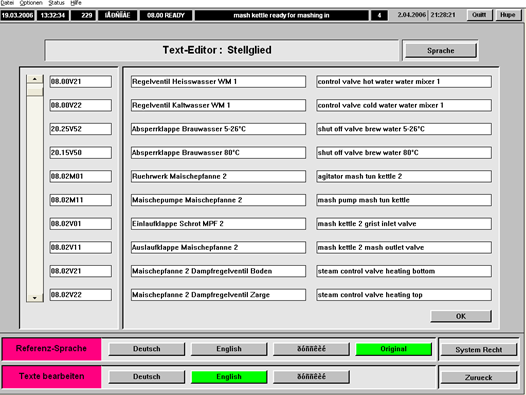

Multi language

BatchGuide is one of the first systems in the world to incorporate multilingualism into their system that allowed it for project to be develop for different parts of the world, without any limitation for crating an suitable user-interface for each region. BatchGuide had many more applications that made it competitive and being on the cutting edge of technology at the time. We will not go further into these applications as they will be addressed later when we discuss the BatchXpert system.