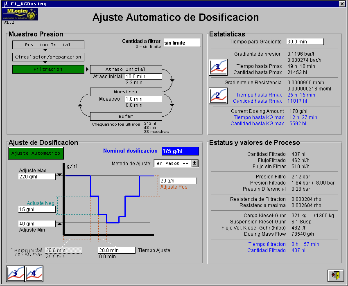

If you are using any soft of Kieselguhr filtration in your process, horizontal or modern cande filtration, it is crucial to have reliable and efficient control and monitoring of the dosage of filtration earth, to obtain the optimum efficiency of the Kieselguhr filter. Our Automatic Filtration Earth Dosing System implements a control based on an intelligent monitoring and control of the dosage amount of filtration earth for candle filters and horizontal plate filters, seeking to improve mainly three points of the current system:

- Optimization of filtration times.

- Anticipate possible changes in the process conditions to react appropriately, giving greater stability to the process.

- Greater process stability

- Eliminate monitoring and monitoring of operators in the dosing process.

- Reduce the amount of filtering soil used in filtration

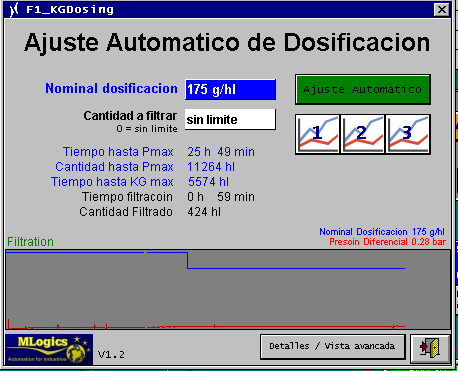

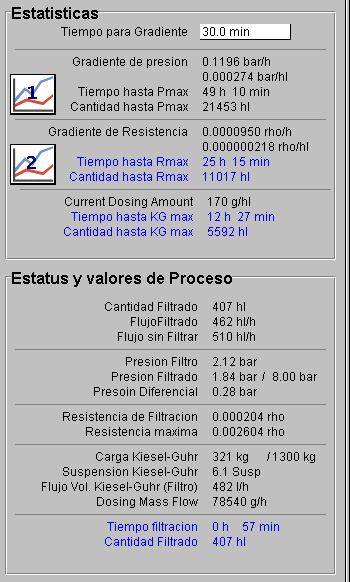

The system implements an automatic regulation of the dosage amount of filtering soil for a filter of candles with Kieselguhr. This system will automatically optimize the use of filtering soil to achieve a longer filtration time considering the current parameters and behaviors (pressure, flow, optionally turbidity).

The control allows to anticipate possible changes in the process conditions (such as an excessive increase in the quantities of yeast caused by a change of the filtration tank), acting accordingly and regulating the necessary nominal values in real time for optimal clarification, Maximizing process efficiency. The system constantly monitors the behavior of the filter pressure, always considering the optimum performance, and uses these values to determine the amount of filtration land to be metered.

Optionally it is possible and advisable to connect a turbidity measurement, at the inflow of the unfiltered buffer tank, to the filter inlet. This measurement allows to deliver information about the incoming beer to the filter and thus enables the regulation to better anticipate possible increases of yeast inside the beer, and thus achieves better stability of regulation.

Due to the open design of the system, this can be applied to virtually all soil metering filters (Candle Filters and Horizontal Filters) of all brands. The control can be integrated into the existing filter control system, or as part of a re-automation of a manual filter. In general the system requires a minimum of instrumentation for its operation:

- Flow meter for measuring the filtered product

- Pressure sensor in the filter container

- Pressure sensor in filtered product line

- Optionally turbidity sensor in the unfiltered product line

If you are interested in applying an advanced and predictive system in your processes, do not hesitate to contact us.